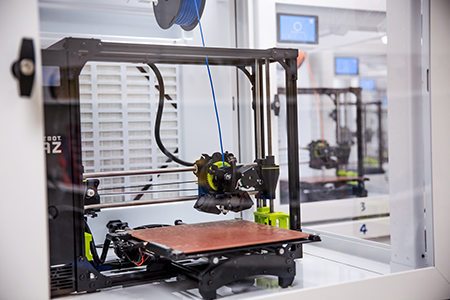

Kettering University students can now bring their design ideas to life with ease thanks to the new 3D Printing Factory on campus.

Located in the C.S. Mott Engineering and Science Center, the 3D Printing Factory houses 12 3D printers available for students of all majors and faculty to access as part of a class project or an extracurricular project.

“Students can hold the part they designed in class in their hands. It closes the loop for the missing piece in our engineering design courses,” said Dr. Craig Hoff, dean of Kettering’s College of Engineering. “The new lab allows students to take their ideas, design it on the computer, and then see the finished product. Until you hold the part in your hand you don’t realize what you’ve done.”

Although there is limited physical access to the spaces, projects can be remotely sent to the 3D printers and picked up when they are complete. Lab technicians are available to take out completed projects and keep up the equipment.

“By having 3D printers students can do more projects, more group work, and more design work,” said Dr. Bassem Ramadan, Mechanical Engineering Department Head. “There are at least six different capstone courses that the 3D Printing Factory will benefit, and now all students will be able to make design projects tangible, as well.”

With 3D printing becoming more popular and prevalent in industry, having access to the technology is important for Kettering students, Ramadan said. Students can easily print a prototype of a part and see how it looks and works. This experience will benefit them when they are in the workforce, he said.

“Visually it is important because you see it on the computer screen, but you don’t see the details and the depth of the prototype. When you print it you can see those and examine the details,” Bassem said.

Charles Gates ‘19, a Mechanical Engineering graduate student at Kettering, used the new lab to print a box to hold equipment for the AutoDrive Challenge car. It was helpful to have access to facility with easy 3D printing capability, Gates said.

Having the 3D Printing Factory encourages creativity, which is important for a STEM university, Gates said.

“It was very convenient to use. A standard box was not the right size and shape for the AutoDrive vehicle. After figuring out the wiring for the equipment inside and resizing it, the 3D printed box allowed for a better fit that we could not have bought in stores,” Gates said. “Having a 3D printer lab on campus is great and I’m very excited that students can use it. It allows me to create objects that fit what project I am working on and not limit myself to stuff I can find in the store. I think a lot of other students will be excited when they find out all the things they can do with 3D printed materials.”